Category

Chemical Process Equipment (Enamel reaction tank)

enameled reaction tank >>Enamel reaction kettle is comprised of two basic components----steel vessel and glass liner. Th

Basic Info

| Model NO. | DN1000-DN2800 |

| Professional Manufacturer | High Quality, Low Price |

| Customized Design | Amse Certification |

| Application | Heater, Cooler, Vaporizer, Condenser |

| Structure Material | Metal Material |

| Heat Transfer Surface | Tubular Heat Exchanger |

| Principle | Mixing Heat Exchanger |

| Transport Package | Non-Package,Iron or Wooden Pedestal,Suitable for I |

| Specification | 50L-5000L |

| Trademark | DeChuang |

| Origin | Shangdong China |

| HS Code | 66 |

| Production Capacity | 500 Sets Per Year |

Product Description

enameled reaction tank

>>Enamel reaction kettle is comprised of two basic components----steel vessel and glass liner.

The steel vessel is lined with silica glass, and high temperature makes two components become

a new compound. As a result, possessing stability and high strength, the kettle has good

performance in organic acid/mineral acid/organic solvent resistance.

The enamel reaction kettle is applied in chemical industry, petroleum refining, smelting, electrolytic industry

and pharmacy, etc.

Features:

1.Corrosion resistant and non-invasive

2.Easy installation, maintenance and replacement

3.Long operating life

4.Good sealing performance

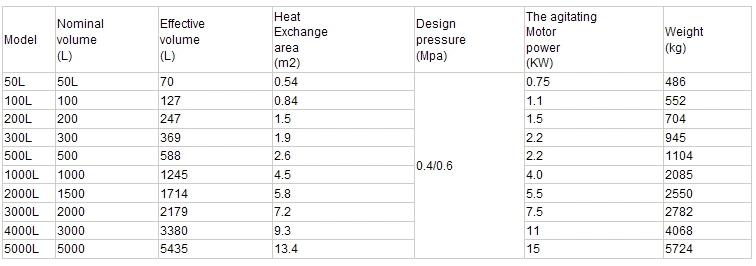

Enamel reaction kettle - Technology parameter